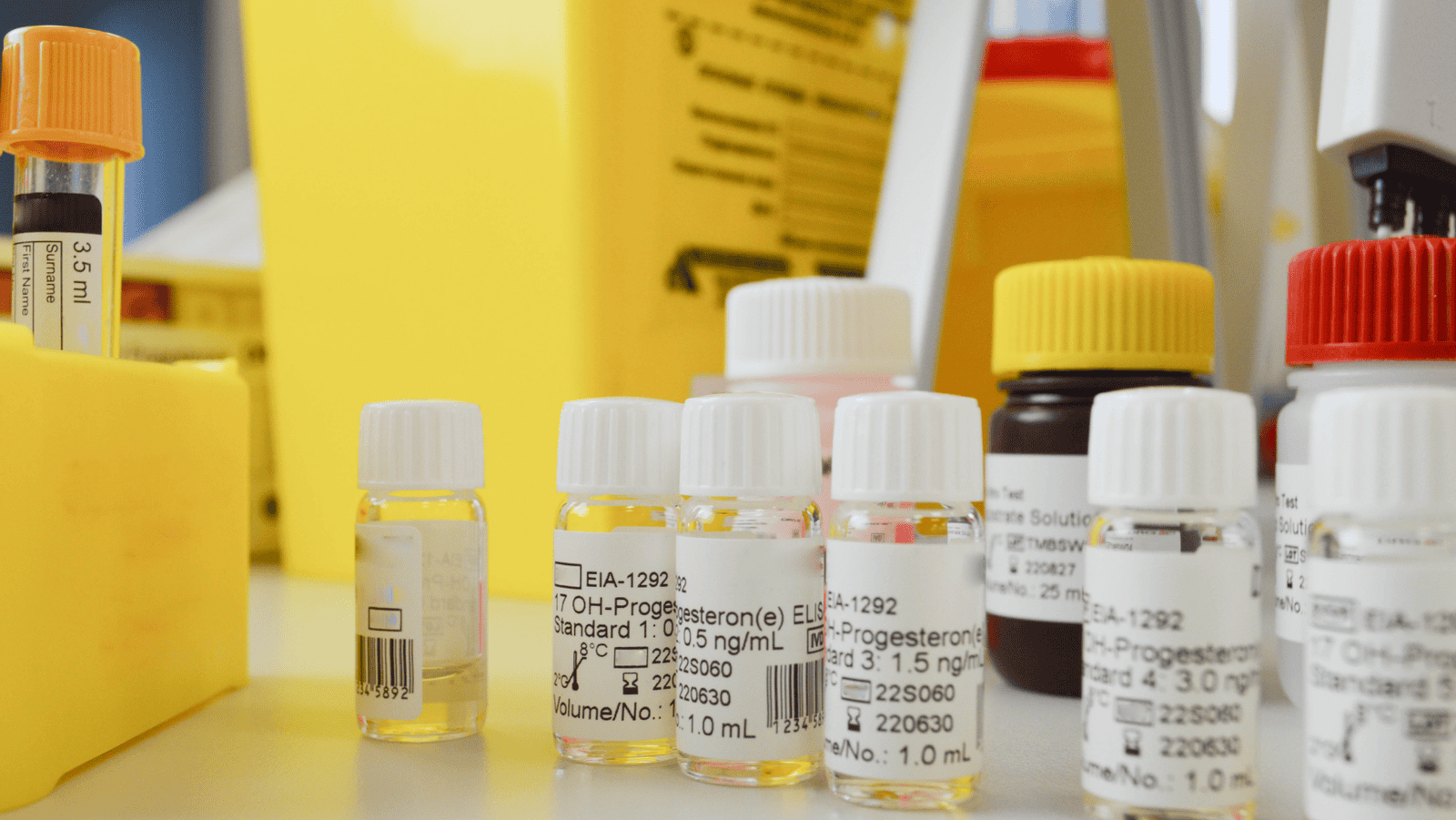

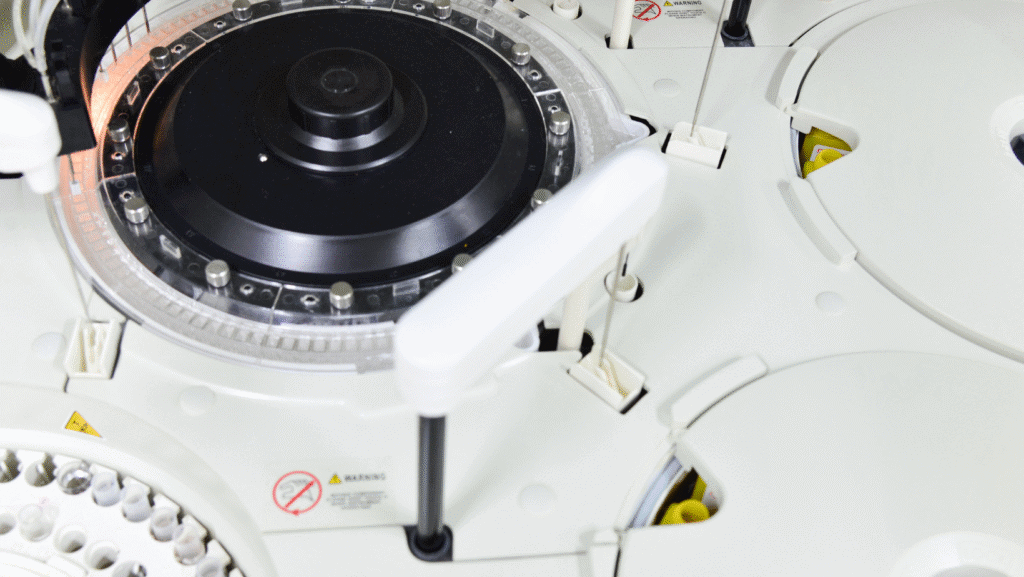

In laboratory diagnostics, even the most advanced analyzer can only deliver accurate results if paired with high-quality reagents. Whether you're running a busy hospital lab or operating a point-of-care testing (POCT) station in a rural health unit, the quality of lab reagents directly affects your analyzer’s accuracy and, ultimately, patient care.

This blog explores how lab reagent quality influences clinical results, the risks of using substandard reagents, and what to look for when sourcing diagnostic materials for your laboratory.

Every reagent used in a test contributes to the chemical reactions that your analyzer interprets. From hematology to biochemistry to immunoassays, reagent precision defines test precision.

Poor-quality reagents can lead to:

According to the Clinical and Laboratory Standards Institute (CLSI), reagent variability accounts for a significant portion of analytical errors, particularly in decentralized or manually calibrated systems.

RELATED READING: Electrolyte Testing in Diagnostics: Why It Matters

An analyzer’s performance depends on the consistency, composition, and stability of the reagents it uses. Here’s how:

Even top-tier analyzers cannot compensate for poor reagents. Precision instruments interpret chemical reactions based on specific thresholds. If reagents don’t perform as expected, analyzer accuracy suffers, even if the machine is working perfectly.

RELATED READING: Coagulation Testing: A Comprehensive Guide

Accurate diagnostics lead to faster interventions, fewer complications, and better patient trust. On the flip side, inconsistent results can undermine treatment decisions, delay recovery, or cause unnecessary stress for both clinicians and patients.

Examples of Diagnostic Reagent Impact:

Statistic to Highlight:

According to the WHO, 60-70% of clinical decisions are based on lab results. Reliable reagents are therefore essential for clinical confidence.

Enhance accuracy with the right diagnostic pairing—browse our products here.

When sourcing laboratory reagents, especially for automated analyzers or POCT devices, pay attention to:

| Criteria | Why It Matters |

| CE/ISO/FDA Certifications | Verifies quality control and manufacturing compliance |

| Instrument Compatibility | Ensures full reactivity and optimal performance with your analyzer |

| Stability in Tropical Climate | Reduces degradation risk during storage or transport |

| Technical Support Availability | Allows quick troubleshooting and reduces system downtime |

| Lot Verification and Traceability | Facilitates error tracking and quality audits |

Reagent quality is one part of the equation. To protect diagnostic integrity, also consider:

What makes a reagent “high quality”?

Reagents with validated composition, stable performance, and certifications (e.g., ISO 13485, CE-marked) are considered high quality.

How do I know if poor reagents are affecting my analyzer?

Watch for repeated QC failures, frequent recalibrations, or inconsistent test results. These could indicate reagent-related issues.

Can I use third-party reagents with branded analyzers?

It depends. Some systems allow open reagents, but many perform best with manufacturer-approved kits to maintain accuracy.

What’s the shelf life of diagnostic reagents?

It varies by type. Always check packaging and store according to the manufacturer’s guidelines.

Is local climate a factor in reagent performance?

Yes. High humidity and heat can degrade sensitive reagents. Choose suppliers that offer climate-suitable solutions.

Reliable diagnostics begin with quality inputs. Investing in high-grade reagents ensures analyzer accuracy, protects clinical decisions, and supports your lab’s credibility. For diagnostic laboratories in the Philippines, where healthcare needs continue to grow, lab reagent quality is not a luxury—it’s a necessity.

Staying informed, auditing your supply chain, and educating your team are all steps toward safeguarding test integrity and better patient outcomes.

Minimize errors. Maximize confidence. Understand the power of reliable reagents in diagnostics.